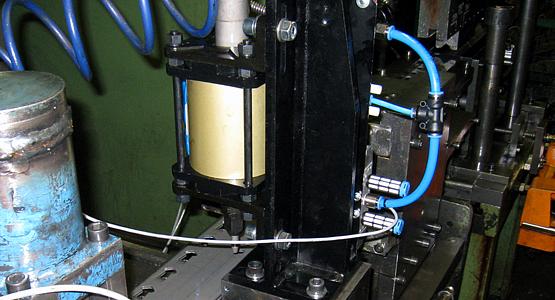

Marking by impact machine in production line

This cylinder has marked over 4 millions parts

Million of impacts nonstop

We delivered several pneumatic impact valves to the customer, who produces steel industrial racks. The valves are installed within the production line, which took its working cycle for own marking.

In this case, simple signs are marked, logos or another type of information may be marked as well. Whole marking device works perfectly in 24/7 continuously, with minimal working costs. It reaches high working cycle: 4.000 pcs per 7.5-hour shift, now. Marking device did more than 4 million parts since 2008!

We delivered several pneumatic impact valves to the customer, who produces steel industrial racks. The valves are installed within the production line, which took its working cycle for own marking.

In this case, simple signs are marked, logos or another type of information may be marked as well. Whole marking device works perfectly in 24/7 continuously, with minimal working costs. It reaches high working cycle: 4.000 pcs per 7.5-hour shift, now. Marking device did more than 4 million parts since 2008!

Reliability for minimal costs

Hundreds even thousands of such installed Automator marking impact devices work all around the world. The reasons for the pneumatic valve acquisitions are deep direct marking onto the material, stability, and irremovability of marks and high marking speed. Last but not least is easy integration into working line and simple pneumatic drive.

As a bonus, you get lower purchase costs and longer life in service.

Hundreds even thousands of such installed Automator marking impact devices work all around the world. The reasons for the pneumatic valve acquisitions are deep direct marking onto the material, stability, and irremovability of marks and high marking speed. Last but not least is easy integration into working line and simple pneumatic drive.

As a bonus, you get lower purchase costs and longer life in service.

Do you need anything similar?

We prepare a solution which fits your business.